Fully Equipped Pressure-Sensitive Release Liner Manufacturing Plant

Designed for the production of silicone-coated paper and film liners serving label, tape, medical, and industrial markets. The facility remains installed and in good condition, with several major systems installed as recently as 2023.

The plant includes extrusion and gravure coating lines, slitter rewinders, flexographic printing, robotic roll handling and wrapping systems, mobile material-handling equipment, core cutters, storage silos, air compressors, and a well-equipped maintenance shop.

Product Capabilities:

Silicone-coated paper and film release liners

Pressure-sensitive label stock

Double-sided tape liners

Medical adhesive liners (e.g., electrode patches, wound dressings)

Graphic films and decals

Industrial release liners for electronics, automotive, and construction applications

The coating lines are capable of applying silicone, primers, barrier coatings, and adhesives to a variety of substrates, including PET, PP, PE, kraft paper, and glassine.

Major Assets Include:

(1) Tandem (Double-Sided) Extrusion Coating Line – 72" wide, turret unwind, (2) corona treaters, primer station, single-pass gas flotation dryer, 6" extruder, Cloeren EBR auto die, chill roll, turret rewinder.

(1) Gravure/Offset Coating Line – 64" wide, turret unwind, gravure carts, flame treater, mixing kitchen, flotation dryer, chill rolls, vision system.

(1) Mayer Rod Coating Line – 63.5" wide, turret unwind, flexo station, Mayer rod, gravure coating, gas dryer, chill rolls, moisture injection systems.

(1) Pilot Mayer Rod Coating Line – Approx. 34" wide, unwind stands, coating heads, gas dryers, UV curing, control consoles.

(3) Slitter Rewinders – (2) Black Clawson DR-50 LH, (1) Cameron T.640 (upgraded).

(1) 2-Color Stack-Type Flexographic Printer – 63" wide, chamber doctor blade, gas dryer, web guides.

Automated Roll Handling & Packaging – (3) AGVs (2021), robotic roll wrapping & palletizing system (2022) with Fanuc robot, glue unit, revolver wrapper, conveyors.

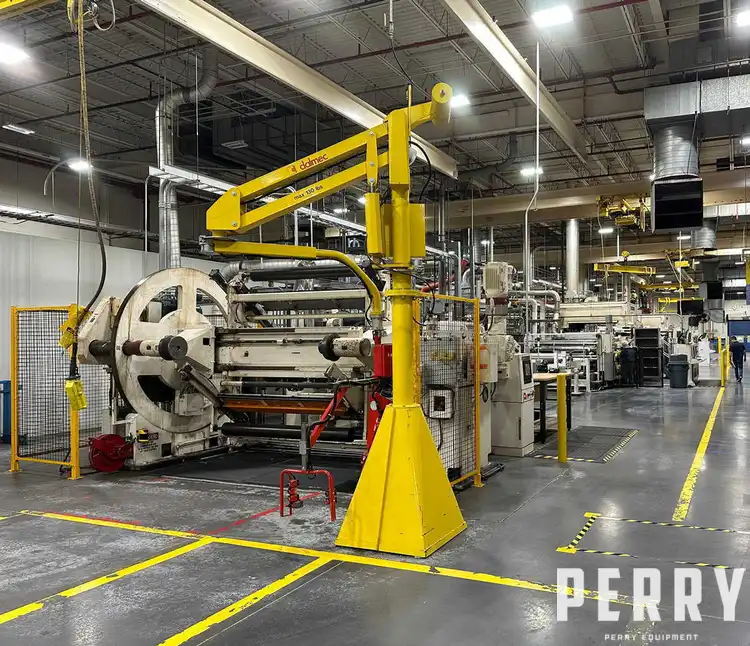

Pneumatic Manipulators & Roll Handling – Dalmec units (2012–2018), roll upenders, manual roll presses, Wulftec stretch wrappers.

Core Cutters & Auxiliary Equipment – (3) Appleton core cutters, manual wrapping stations, pneumatic presses.

Compressed Air System – (4) rotary screw compressors, 50–100 HP.

(3) Steel Storage Silos – 7,737 cu. ft. each, for LDPE/HDPE materials.

Mobile Equipment – Electric forklifts including (4) 2023 Caterpillar 2ET4000 trucks, Genie boom lifts, Yale/Clark/Roll Lift trucks, walk-behind stackers, pickup truck.

Maintenance Shop – Lathes, vertical mill, band saws, grinders, presses, dust collection system.

We use cookies to improve your experience. Privacy Policy.