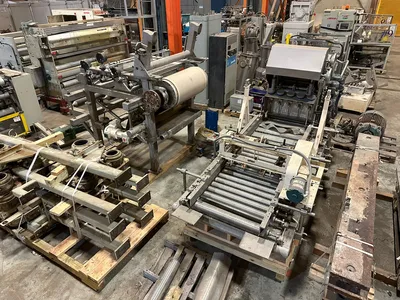

Used 24" (609 mm) Laboratory Paper Machine

Max Operating Speed: 20 feet/min (6.1 meters/min)

Basis Weight Range: 24–210 lb/480 ft² (≈39–343 g/m²)

Product Width: 24" (609 mm) trimmed

Condition: Reported under 300 hours of use

Major Components:

Headbox:

Stainless steel Hogenkamp headbox with 27" pond width

Equipped with (2) internal dilution rolls and bar thickness adjustment (6–60 mil)

Forming Section:

Stainless steel Fourdrinier table approx. 12 ft (3.7 m)

Includes (14) felt rolls and (3) stainless suction boxes

12" OD breast roll

Press Section:

(2) LG Industries press sections with rubber-covered blind-drilled rolls

Capable of high and low pressure pressing (up to 500 PLI)

Configurable for minimal-pressure or no-pressure gauge control applications

Dryer Section 1:

(10) Dryer cans: (9) Sandy Hill, (1) Black Clawson

Size: 48" x 36" (1220 mm x 915 mm), National Board stamped, 150 psi (10.3 bar)

Shell thickness 7/8", head thickness 1-1/4"

Inclined Coater:

Air-operated S-wrap type design

Dryer Section 2:

(6) Dryer cans: (3) Sandy Hill, (3) Black Clawson

Same specifications as Dryer Section 1

Calender:

LG 2-roll calender with 16" x 32" (406 mm x 813 mm) top roll

18" x 32" (457 mm x 813 mm) bottom roll with Mt Hope bowed roll and idler

Winder:

Surface-type winder with 32" x 16" (813 mm x 406 mm) drum

Stock Preparation & Ancillaries:

Refiner: Andritz R12MA single disc refiner

Pulper: Black Clawson stainless steel, 36" dia., bottom discharge, motorized, dated 9-70

Screen: Sweco 30" vibrating screen

Pumps: (2) Nash vacuum pumps, multiple Goulds process pumps

Tanks & Agitation:

(4) Fiberglass open-top tanks, approx. 500 gal (1890 L) each

9' tall with dish bottoms, Lightning 1.5 HP agitators, SS shafts with dual impellers

(2) Raven fiberglass tanks, 1000 gal (3785 L) each, with agitators

(1) Stainless steel tank by Baeuerle and Morris, approx. 3000 gal (11,350 L), cone bottom

Utilities:

Steam:

1250 lb/hr @ 125 psi (dryers)

2100 lb/hr @ 10 psi (white water system)

Electric Power: Total load approx. 392 KVA

Air: 80 SCFM @ 80 PSIG

Water: 60 GPM @ 40 PSIG

Notes:

Previously used as R&D to produce filter papers and specialty grades including high-performance fiber papers (e.g., Kevlar, synthetic blends)

Capable of product development, pilot trials, and low-speed commercial runs

Designed for sheet consistency range from 1% to 97% (from headbox to after drying)

We use cookies to improve your experience. Privacy Policy.